UHF RFID Labels with LED light for File Management

UHF RFID Labels with LED light for File Management

UHF RFID Labels with LED light

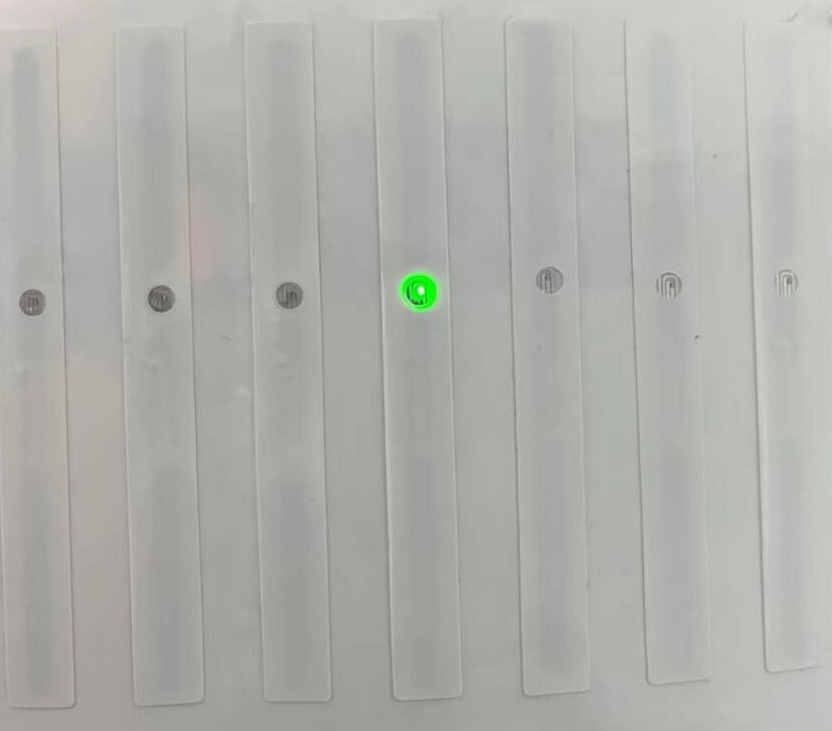

1. UHF LED light tag based on TID UID EPC specified numbers for inventory check, it reduce labor cost 80% more than human operation, improved track efficiency, track capacity and track accuracy.

2. UHF LED light tag is good used for pick-to-light purpose.

3. Prevent mistaken & repeated operation take out/put back items from warehouse, pallets, Especially prevent risky and

damages during lift up/ lift down some goods that you are looking for.

4. UHF LED light tag active response to the inventory reader with LED lighting indicator.

How Does It Work?

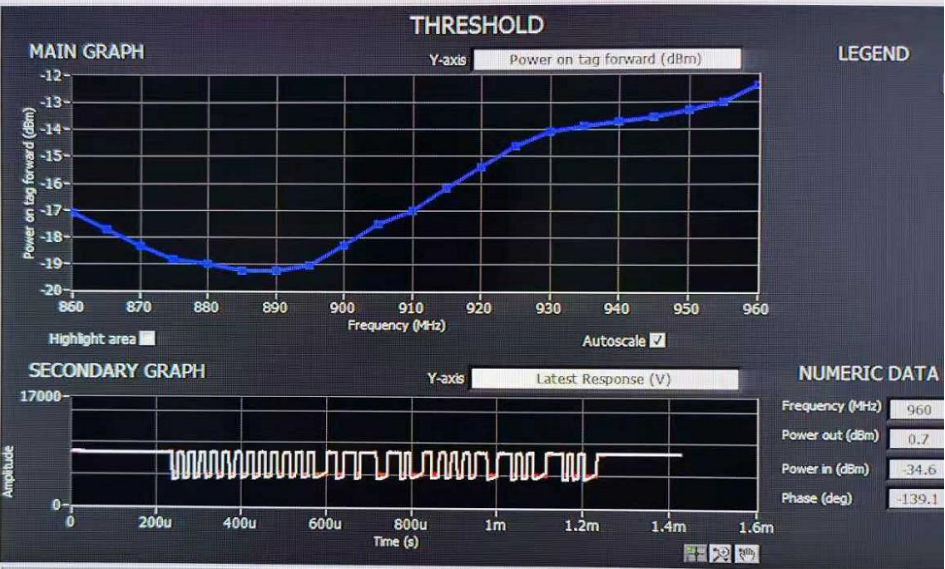

An RFID system consists of a tag, which is made up of a microchip with an antenna, and an interrogator or reader with an antenna. The reader sends out electromagnetic waves. The tag antenna is tuned to receive these waves. A passive RFID tag draws power from field created by the reader and uses it to power the microchip’s circuits. The chip then modulates the waves that the tag sends back to the reader and the reader converts the new waves into digital data.

Product Specification:

| Material | Printable white paper |

| Adhesive | Yes |

| Label size | 98*12mm |

| Thickness | 0.2mm |

| Chips Available | UHF |

| Frequency | 860-960MHZ |

| Protocol | ISO18000-6C |

| Working temperature | -35℃ – 85℃ |

| Reading Distance | 0.5-1.5 meters ( depends on reader) |

Application: