Vingcard RFID Prelam/inlay sheet semi product for contactless card

$0.06-1.3

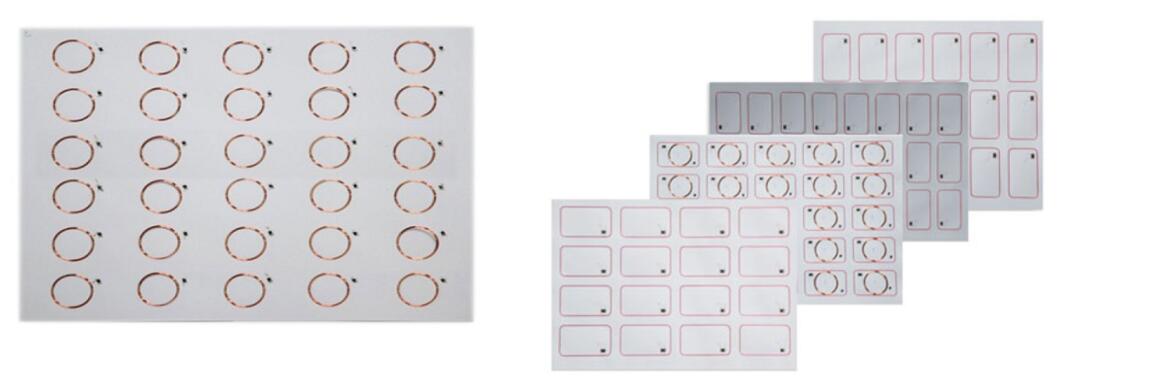

Compare with RFID prelam is a semi finish product which is used for making RFID cards. , also named rfid card inlay, contactless card inlay, it is the core part of RFID card.

Vingcard RFID Prelam/inlay sheet semi product for contactless card

Product Description:

| Material | PVC/PET |

| Color | White or Transparent |

| Standard | ISO11784/11785, ISO14443, ISO15693, ISO 18000, etc. |

| Dimension | 310*468mm, Max. size 520*420mm, A4 210*297mm, etc. |

| Layout | 2*5, 4*5, 5*5, 4*6, 4*7, 4*8, 4*10, 3*6, 3*7, 3*8, 6*7, 6*8, 6*14 or customized. |

|

Thickness |

HF: normal 0.45mm/0.5mm LF: normal 0.55mm/0.5mm UHF: 0.5mm, 0.45mm |

|

Antenna |

LF: Pre-winding Copper Coli, AL Etching |

| HF: AL Etching, Pre-winding Copper Coil, Ultrasonic Embeding | |

| UHF: AL Etching | |

| Work Temperature | -25℃ ~ +55℃ |

| Store Temperature | -25℃ ~ +65℃ |

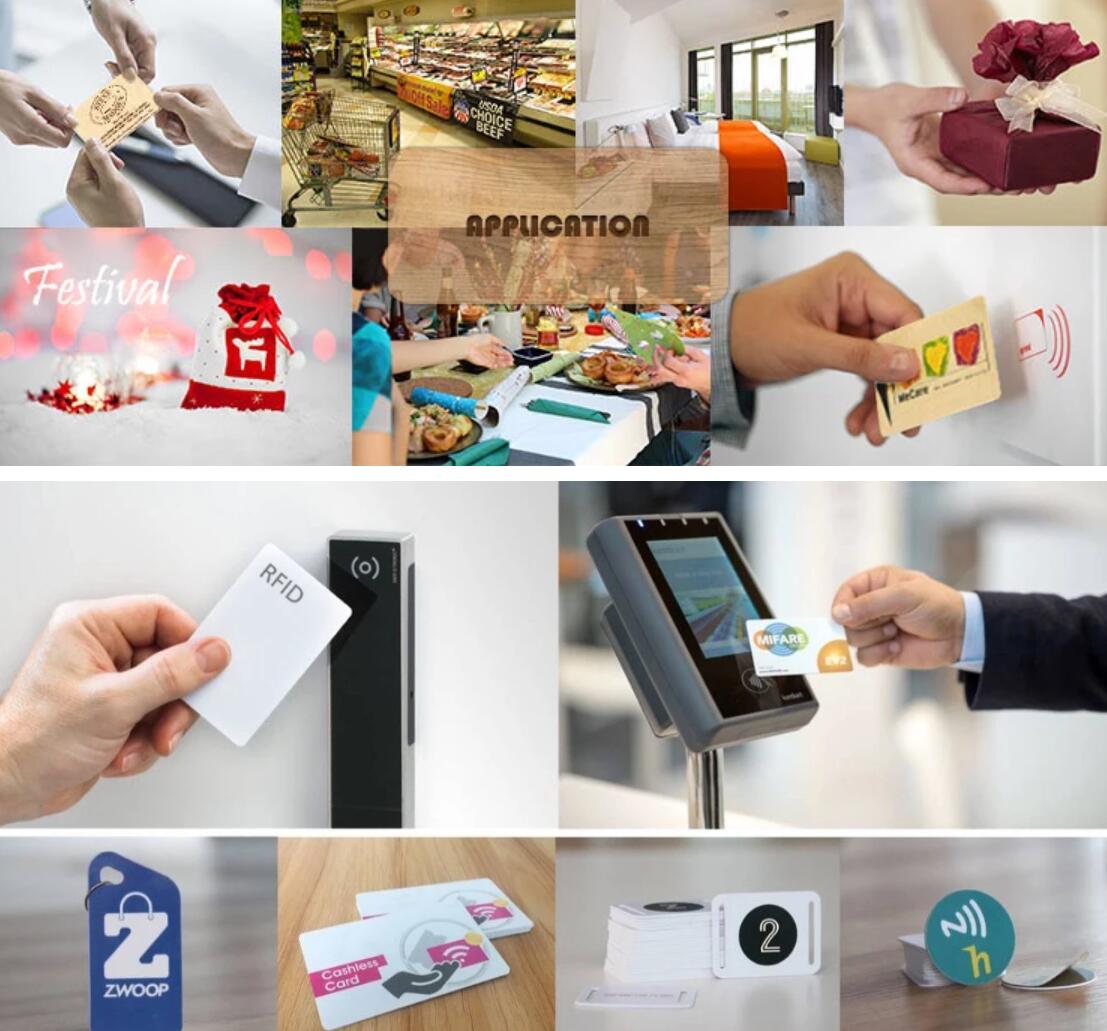

| Applications | Access Control & Security, Time Attendance, Logical Access, Public Transport, City Card, etc. |

Vingcard RFID Prelam/inlay sheet semi product for contactless card

Compare with RFID prelam is a semi finish product which is used for making RFID cards. , also named rfid card inlay, contactless card inlay, it is the core part of RFID card.

RFID inlay sheet Features

The shape and size of the antenna can be adapted to specific needs,

Customized layout and thickness

Trimmed reference edges and optional printed marks to make the further process more easy.

An RFID system consists of a tag, which is made up of a microchip with an antenna, and an interrogator or reader with an antenna. The reader sends out electromagnetic waves. The tag antenna is tuned to receive these waves. A passive RFID tag draws power from field created by the reader and uses it to power the microchip’s circuits. The chip then modulates the waves that the tag sends back to the reader and the reader converts the new waves into digital data.

Application: